A Tale of Two Timelines: Managing Great Expectations with Engineering Realities

“It was the best of times; it was the worst of times” is the opening...

Founded in Central Indiana, Ball Systems partners with global manufacturers to build, replicate, and support custom electrical test systems.

Our execution-first approach blends decades of practical engineering experience with manufacturing discipline to keep systems running and simplify the lives of the engineers we serve.

Ball Systems builds and delivers custom electrical test systems and build-to-print assemblies for production-critical environments.

A universal test platform can replace fragmented, one-off testers with a more maintainable, production-ready approach. This makes engineers' lives easier by standardizing infrastructure and reducing unnecessary complexity.

Download our white paper to learn how we did it.

Custom designed portable test box to emulate factory test in self-contained platform that includes custom firmware, FPGA, etc.

Custom designed NI PXI test console, including custom backplane, card cage, and custom test cards.

Custom wired Virginia Panel (VPC) Interchangable Test Adapter (ITA), this project is custom-designed and wired to provide test interconnect.

Custom designed test circuitry and low-volume production of test cards.

Custom designed, low profile NI PXI test console, including custom backplane, card cage, and custom test cards.

Custom designed PXI Test Console, including NI Chassis and VPC Interconnect.

Test control boxes for major computer OEM server test environment with custom board design and production.

Design and production of high-volume PCAs used in server test environment.

Manufacturing End-Of-Line Gear-Motor Performance Tester

Automation system control panel and enclosure.

Portable suitcase tester for automotive audio systems that is designed to emulate production functional test environment.

8-bay universal programming platform for EEPROM programming and verification with custom PCAs and integrated custom software.

Custom test station for hybrid technology engine control modules that meets high voltage, high power, and automation requirements.

Custom designed programming station to provide simultaneous EEPROM in-line programming in high-speed line.

Custom designed mechanical test stand for hydraulic door closer with a custom software interface with PLC control.

19” rack-mountable programmable custom load box.

Test cabinet houses 32 “conditioning nests” in cell manufacturing environment.

Custom designed engine module tester interface, including custom probe interface, and ergonomic mechanical actuation.

Turnkey contract manufacturing for major railyard and locomotive engineering company.

Custom designed communication board and molded housing that incorporates custom firmware design.

Handheld, portable proprietary communications bus test system.

Turnkey alternator tester.

Custom wired and designed Virginia Panel (VPC) Interchangeable Test Adapter to provide test interconnect.

.jpg?width=173&height=131&name=Interchangeable%20Test%20Adapter%20(ITA).jpg)

Pneumatically actuated, custom designed probe block for testing high-current engine control module for hybrid technology vehicle.

EEPROM verification fixture, including custom mechanical and electrical design and automation.

Custom designed test equipment cable harness, including VPC iCon series quick disconnect and product connectors.

High density, custom backplane design and fabrication.

Custom cable harness design and build.

Custom dishwasher end-of-line audit system.

Custom designed control box for a medical research lab device with precision motion control and vision integration.

Toroidal inductors designed to application, and manufactured in-house.

Hussmann Testing

KPA900 Programmer Software

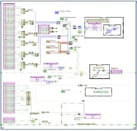

Instrument Oriented design – BallTestTM Sequencer.

Mixed-Signal ASIC Test.

Desktop hardware-in-the-loop test system.

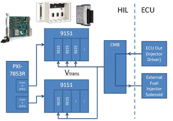

HIL Fuel Injector Measurement System for ECU Tester.

Wireless SBU End of Line Tester.

Fluid Delivery Module Testers.

Designing and Building Six HEV Motor Generator Durability Test Stations.

Universal Configuration and Verification Station for an Industrial Equipment Supplier using NI LabVIEW.

Universal Test Fixtures for Automatic Tank Gauges.

Automotive Programming Station

Automotive Infotainment Suitcase Tester

Ballistics Range Instruments Tester

“It was the best of times; it was the worst of times” is the opening...

Testing…testing…is this thing on? All joking aside,...

No matter the industry you are in, selecting the right suppliers can make or break your business. Choosing suppliers that best fit...

In the manufacturing functional testing environment, quickly building a large quantity of test systems is often necessary to prepare...