+1 (317) 804-2330 | info@ballsystems.com | Blog

+1 (317) 804-2330 | info@ballsystems.com | Blog

Your business challenges do not fit the typical mold. Your test requirements are different. Ball Systems has more than 50 years of experience in multiple industries that has exposed our team to a wide variety of testing applications. As a result, we’ve likely created a solution for a challenge similar to yours.

Your business challenges do not fit the typical mold. Your test requirements are different. Ball Systems has more than 50 years of experience in multiple industries that has exposed our team to a wide variety of testing applications. As a result, we’ve likely created a solution for a challenge similar to yours.

Ball Systems’ capabilities extend from build-to-print to original electrical, mechanical, and software design of test and automation systems. Depending upon your needs, we can leverage specific technologies and in-house expertise to develop the optimal solution to your engineering challenges.

Contact us today to learn how we can help you on your specialized project.

Custom designed NI PXI test console, including custom backplane, card cage, and custom test cards.

Custom designed portable test box to emulate factory test in self-contained platform that includes custom firmware, FPGA, etc.

Custom designed test circuitry and low-volume production of test cards.

Pneumatically actuated, custom-designed probe block for testing high-current engine control module for hybrid technology vehicle.

Design and production of high-volume PCAs used in server test environment.

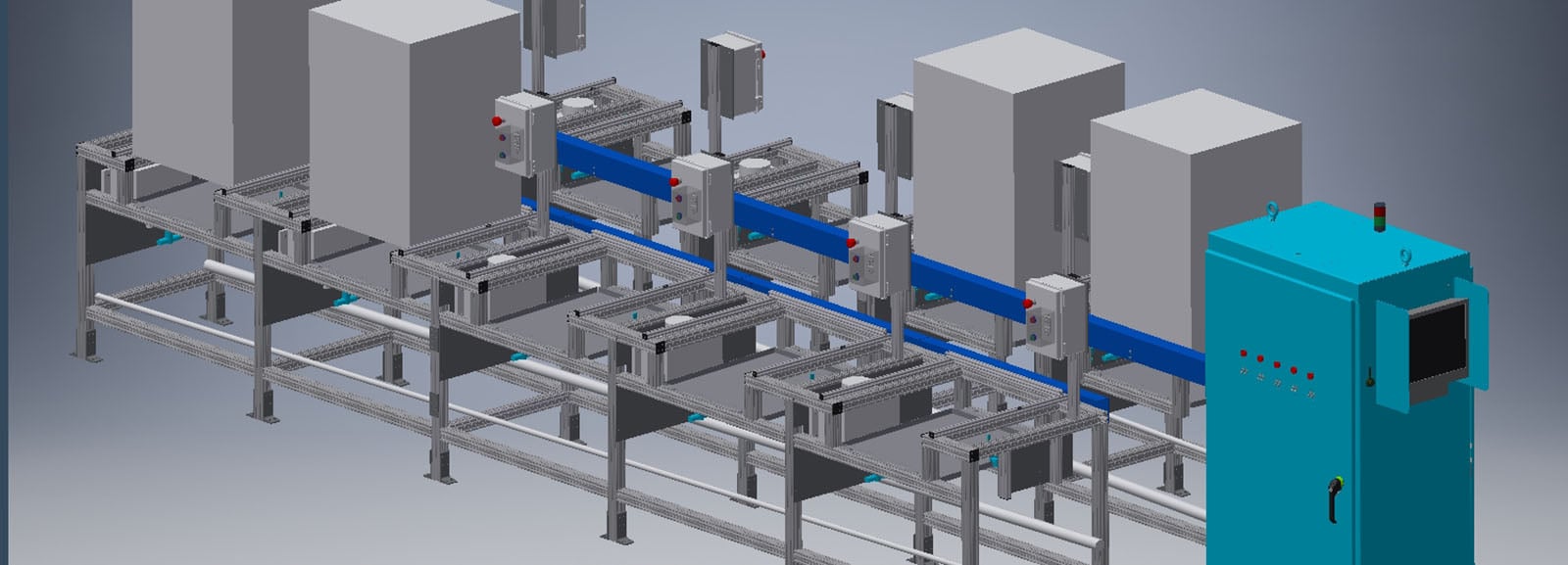

Custom dishwasher end-of-line audit system.

Automation system control panel and enclosure.

Custom test station for hybrid technology engine control modules that meets high voltage, high power, and automation requirements.

Test control boxes for major computer OEM server test environment with custom board design and production.

Pneumatically controlled conditioning nest for engine control module that is custom mechanical, electrical, and firmware design.

Custom designed control box for a medical research lab device with precision motion control and vision integration.

Turnkey contract manufacturing for major railyard and locomotive engineering company.

Custom designed communication board and molded housing that incorporates custom firmware design.

Toroidal inductors designed to application, and manufactured in-house.

Custom wired and designed Virginia Panel (VPC) Interchangable Test Adapter to provide test interconnect.

.jpg?width=173&height=131&name=Interchangeable%20Test%20Adapter%20(ITA).jpg)

EEPROM verification fixture, including custom mechanical and electrical design and automation.

Custom cable harness design and build.

Custom probe blocks and interface circuitry for burn-in cart fixtures.

Custom test cable harness for portable automotive audio system tester.

Portable suitcase tester for automotive audio systems that is designed to emulate production functional test environment.

1U 19-inch power cycling box

Custom designed mechanical test stand for hydraulic door closer with a custom software interface with PLC control.

19” rack-mountable programmable custom load box

Test cabinet houses 32 “conditioning nests” in cell manufacturing environment

Custom designed engine module tester interface, including custom probe interface, and ergonomic mechanical actuation.

Hussmann Testing

KPA900 Programmer Software

Instrument Oriented design – BallTestTM Sequencer

Mixed-Signal ASIC Test

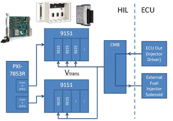

Desktop hardware-in-the-loop test system.

HIL Fuel Injector Measurement System for ECU Tester

Ball Systems designs, develops, and delivers custom test systems and produces comprehensive build-to-print systems for companies creating or manufacturing critical electronic or electro-mechanical components for automotive, aerospace and defense and consumer appliance applications.