Testing…testing…is this thing on? All joking aside, manufacturing test systems are critical to product quality and the long-term success of a program. However, many OEMs are gun-shy about designing and building those systems internally because of potential issues with capacity constraints, schedule risks, and hidden costs.

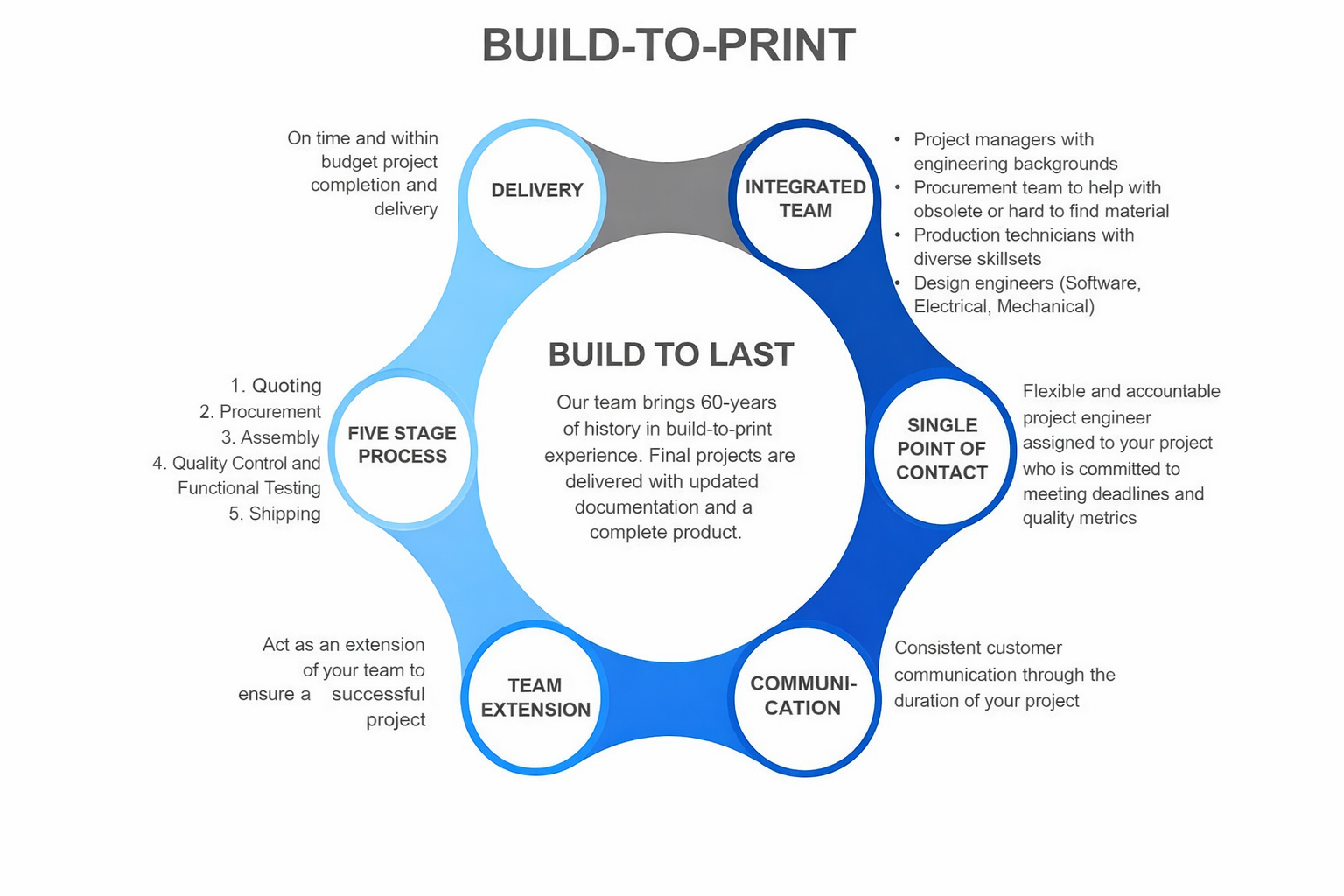

Luckily, there is a solution, in the form of build-to-print test system manufacturing. Build-to-print companies allow engineering teams to keep ownership of their designs while relying on a seasoned partner to manufacture, replicate, and deliver production-ready test systems.

Wouldn’t it be nice to have a test system delivered on time, on budget, and to your exact specifications?

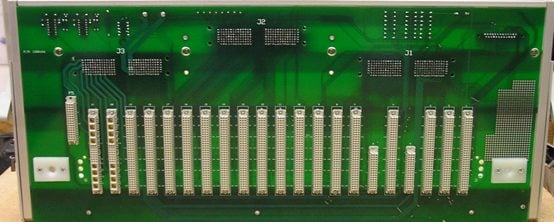

Build-to-print test system manufacturing is an execution-focused model where the customer provides a defined design package, including drawings, schematics, bills of materials (BOMs), software baselines, and specifications to a manufacturing partner which executes the build.

Unlike design-led or platform-driven integrators, a build-to-print test system manufacturer focuses on execution, replication, quality, repeatability, and product readiness.

The goal is not to reinvent the wheel so to speak. Rather, the objective is to build the tester exactly as intended.

This model is commonly used for:

A true build-to-print partnership extends well beyond basic assembly. It encompasses the full manufacturing lifecycle required to deliver production-ready test equipment:

Discipline in execution is what differentiates build-to-print manufacturing from ad-hoc contract assembly.

Learn the 5 Must-Haves for a Strong Build to Print Partner>

It’s simple: build-to-print is the best choice when engineering capability exists, but internal manufacturing capacity is constrained.

Common scenarios include:

In these cases, outsourcing execution reduces risk while preserving engineering design control.

A build-to-print test system manufacturer manages the entire manufacturing execution lifecycle. At Ball Systems, that includes:

This end-to-end execution focus is what repeatable success looks like.

The truth of the matter is that most OEMs don’t need just one test system. They need multiple identical systems across programs, facilities, or production lines. Build-to-print enables this through:

OEMs evaluating build-to-print partners should focus on execution maturity. In Ball Systems’ case, we bring decades of experience in the build to print space to the table.

Strong partners demonstrate reliability, not reinvention. To that end, Ball Systems intentionally operates in an execution-first space to support customers who already know what they need built.

Ball Systems specializes in build-to-print manufacturing and replication of custom test systems across aerospace, defense, automotive, and industrial markets.

Our role is simple:

Build exactly what you’ve designed reliably, repeatedly, and ready for production.

Blog Comments