+1 (317) 804-2330 | info@ballsystems.com | Blog

+1 (317) 804-2330 | info@ballsystems.com | Blog

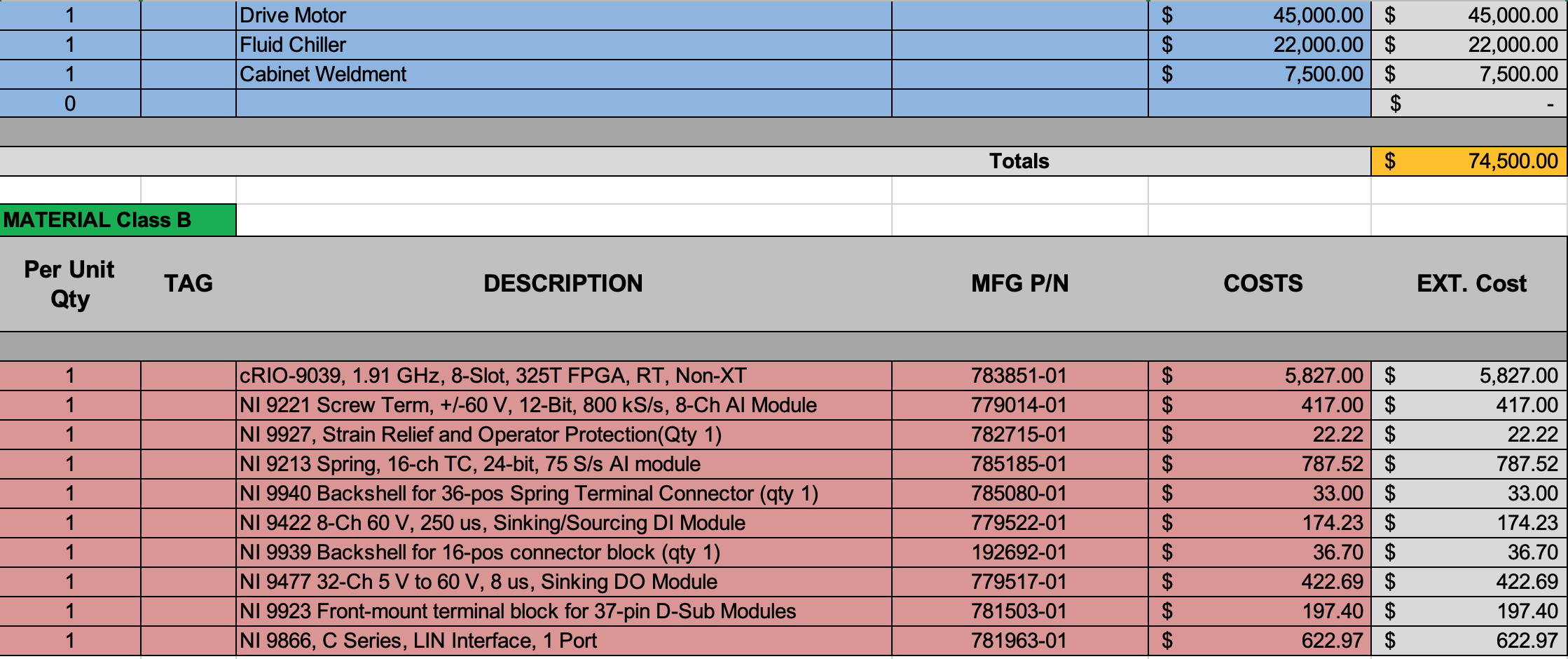

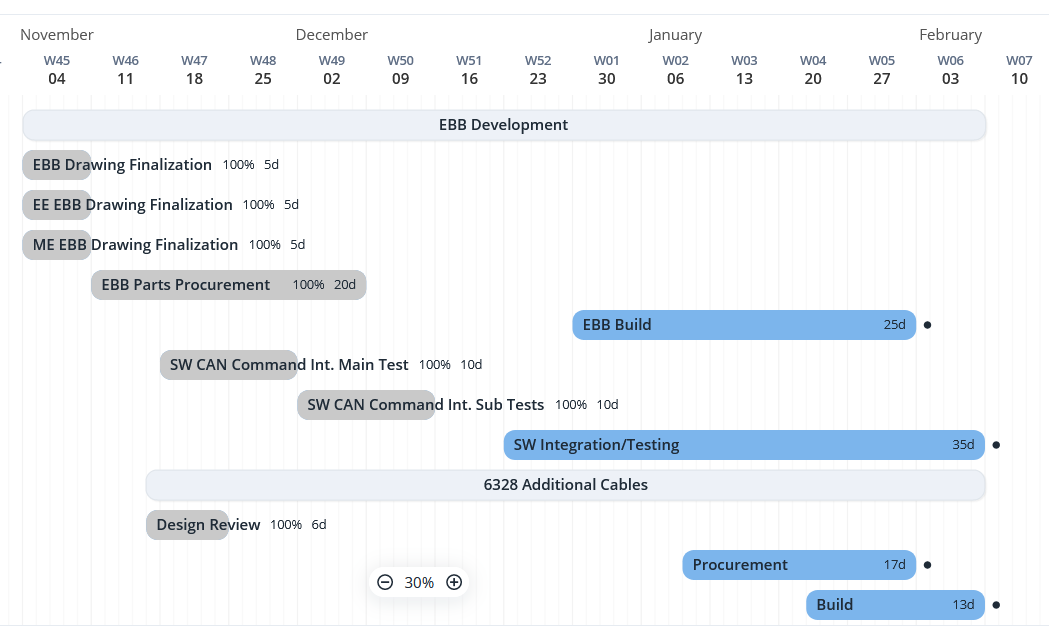

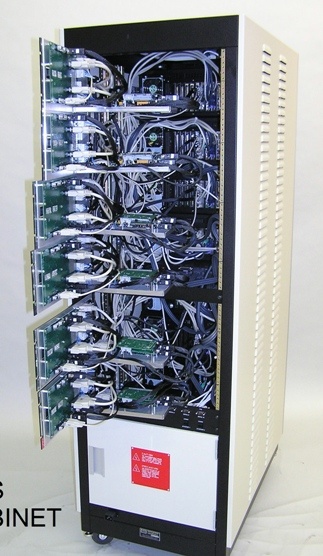

Built-to-print / test system replication addresses your internal capacity and capability constraints. Ball Systems has perfected quoting, procurement, planning, assembly, testing, quality, delivery and installation to ensure your testers are on-time and on-budget, and meet design and production standards while keeping open and transparent communication.

Learn how to increase testing efficiencies across the product development cycle, leverage design-once / use-many solutions, effectively utilize your teams, minimize downstream failures and rework, and build team collaboration to gain consistency.

.jpg?width=553&height=415&name=Interchangeable%20Test%20Adapter%20(ITA).jpg)

Every test system replication project is unique. Our team pulls on multiple areas of expertise to deliver the exact solution you need.

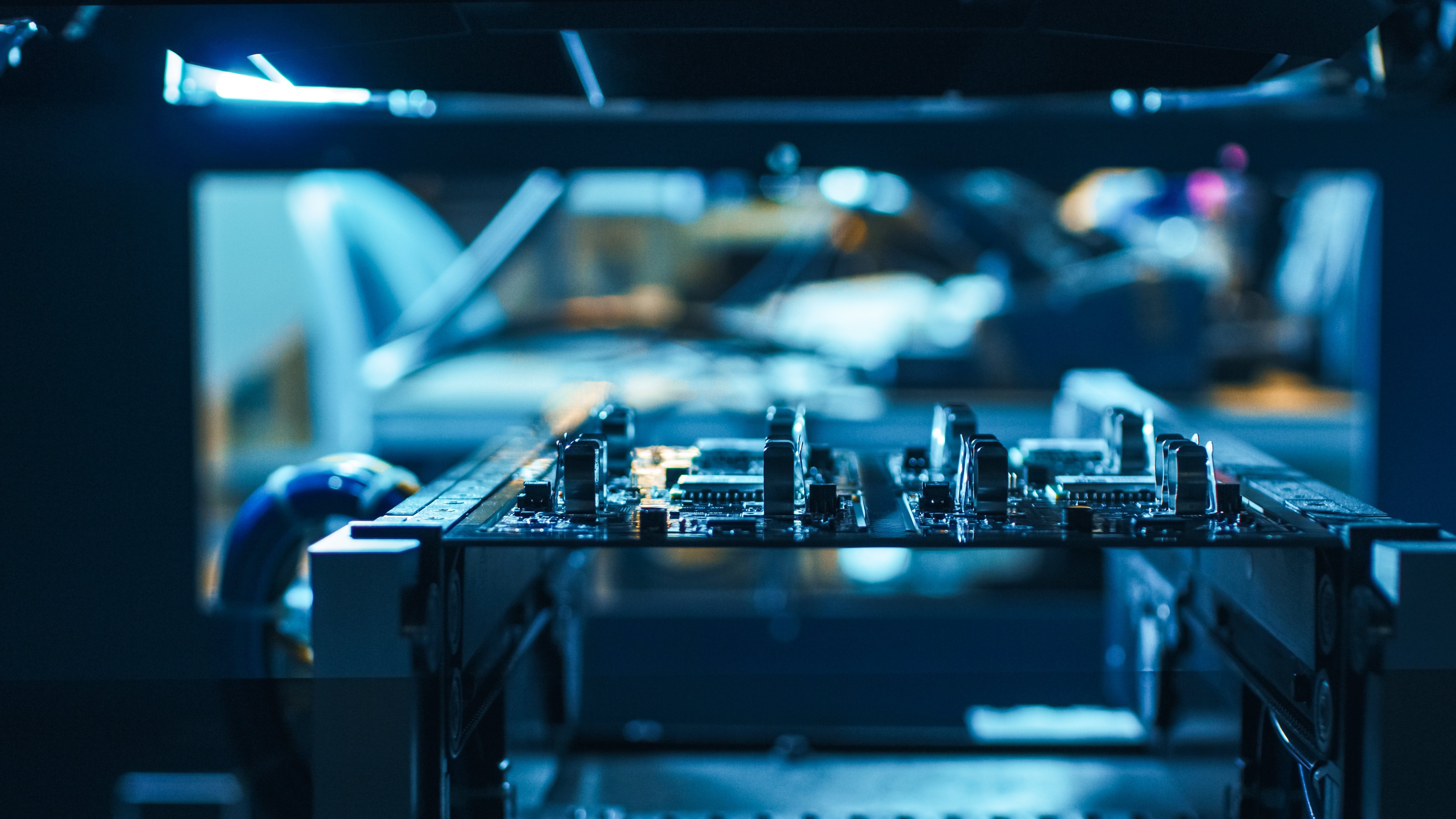

Ball Systems designs, develops, and delivers custom test systems and produces comprehensive build-to-print systems for companies creating or manufacturing critical electronic or electro-mechanical components for automotive, aerospace and defense and consumer appliance applications.