+1 (317) 804-2330 | info@ballsystems.com | Blog

+1 (317) 804-2330 | info@ballsystems.com | Blog

Partner with our experienced team for turnkey custom automated test systems and software solutions to quickly and efficiently run your tests. With our proven test process, we deliver a tester for your unique needs every time.

We know your challenges and tests systems are unique, so we offer a variety of services to meet your needs.

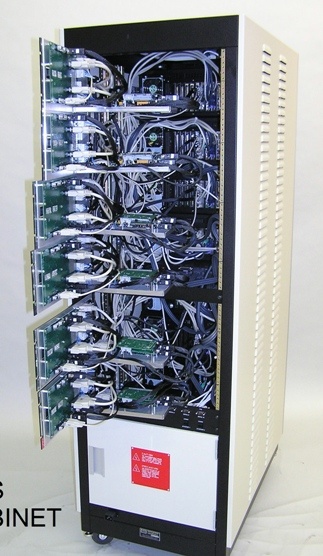

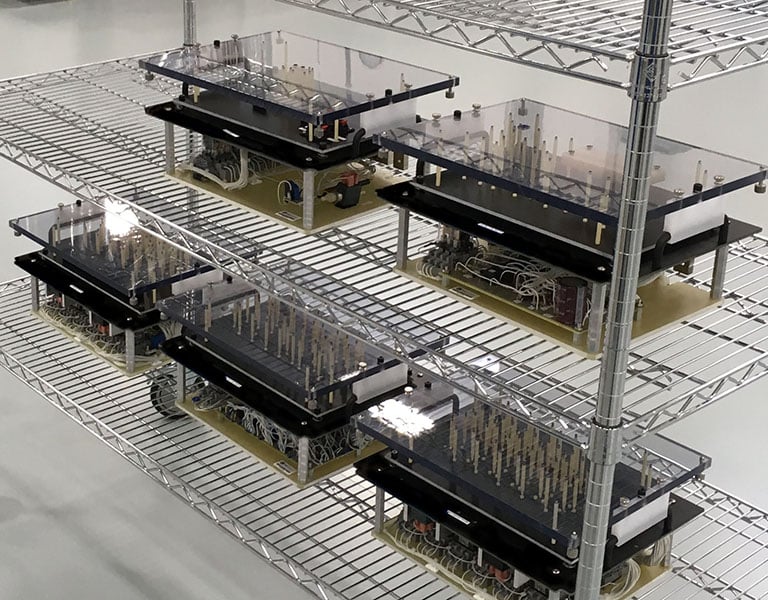

Improving outdated technology, efficiency and flexibility? We’ll take on that challenge any day. Ball Systems helped a global manufacturing leader achieve that when their old one-off system wasn’t up to par due to limited budget and resources.

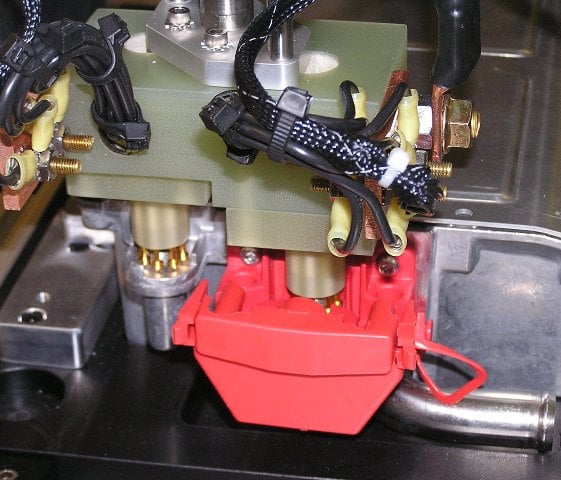

.jpg?width=553&height=415&name=Interchangeable%20Test%20Adapter%20(ITA).jpg)

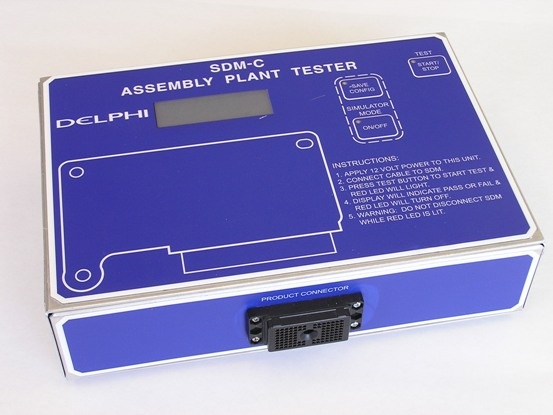

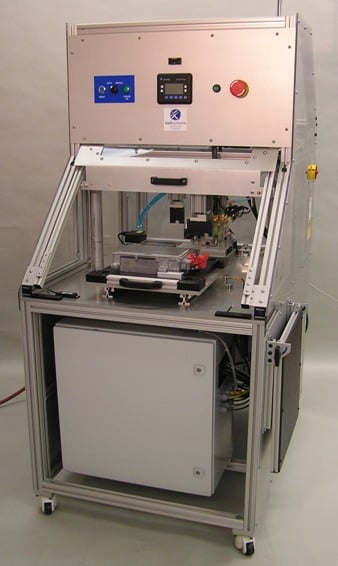

Say goodbye to old technology and one size fits all solutions. See how Ball Systems combines open architecture, commercial-off the-shelf parts and your specific requirements to reduce costs, improve efficiency and meet high quality standards.

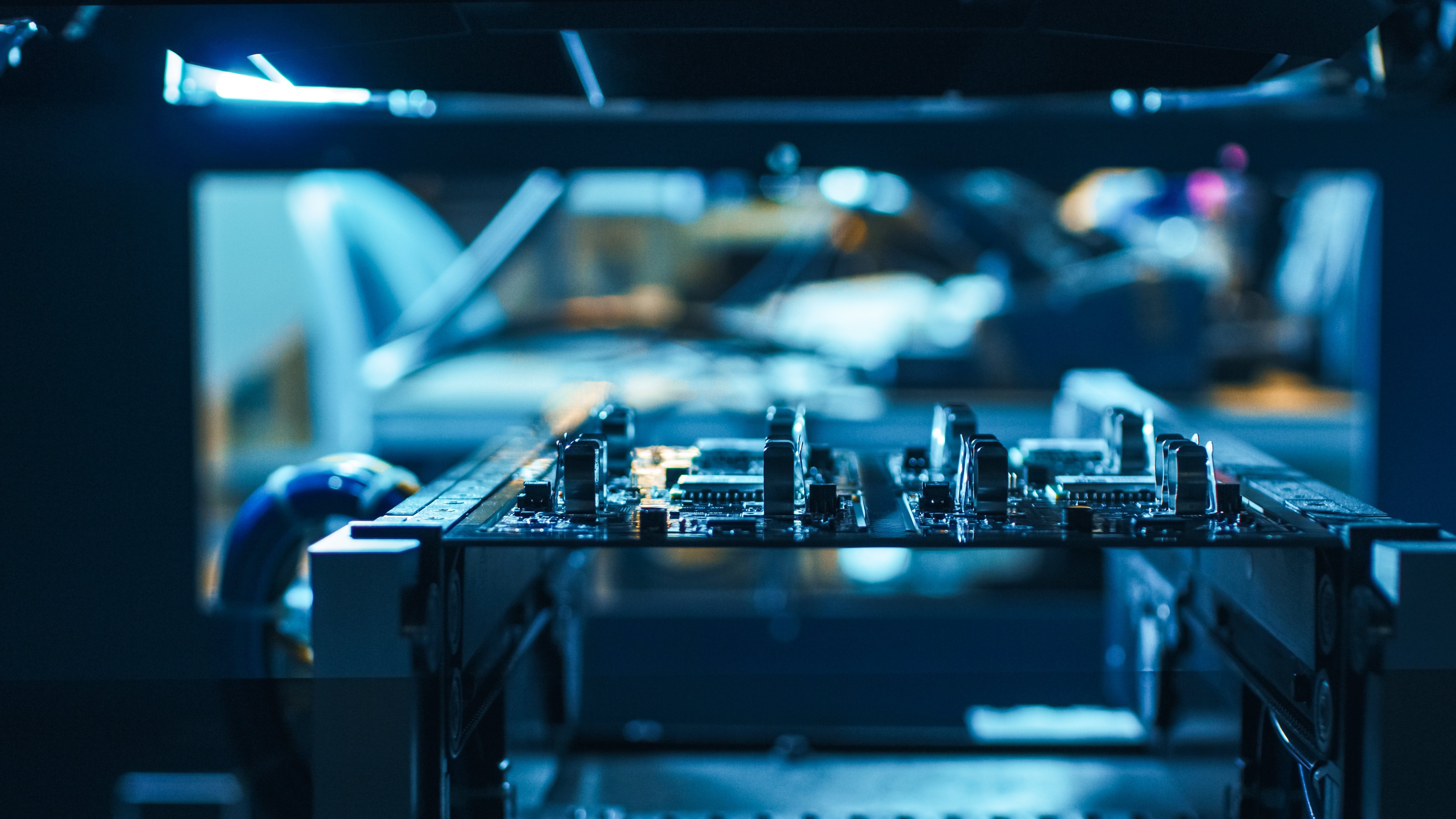

Ball Systems designs, develops, and delivers custom test systems and produces comprehensive build-to-print systems for companies creating or manufacturing critical electronic or electro-mechanical components for automotive, aerospace and defense and consumer appliance applications.