In a manufacturing environment, it is important that products are tested before leaving the facility to ensure the product operates as intended and meets all the specifications laid out for it. Trying to test a wide variety of products can lead to multiple test systems, taking up space and resources. A universal test system can cut down on space and the number of operators required to test your range of products.

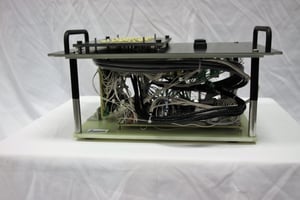

A customer approached us with a test system they had created that used a universal approach to testing a large number of products. The system was developed in house to perform functional testing of various printed circuit board assemblies (PCBA). The system had been added to and modified over the years to adapt to various new products. They requested that we design a more manufacturing friendly and serviceable system for their new production facility. Working with one of our subcontractors who specializes in fixture design, and using our previous experience in designing test systems, we were able to create a test system that is housed in a standard 19” rack and utilizes a convenient mechanism that enables quick changeover from product to product. The system is built around NI PXI chassis, includes various power supplies and interface devices, and uses a Virginia Panel Interconnect system to interface to a base fixture.

The base fixture breaks out all the signals from the test system and allows the customer to drop in various insert nests, each of which corresponds to a different product. By simply pulling a lever, removing one insert nest, and inserting a new nest, the operator can start testing a different product; no tooling is required for changeover.

The nests take up much less space than having a separate test system for each of the products, and only a single operator is required to test the whole range of products. The software that runs on the system will detect the nest that is inserted and will run the test sequence appropriate to that product, that way the operator does not need to change anything in software, it is all handled automatically. This ensures quick, easy, and efficient testing of their whole range of products.

A universal test system can cut down on space, cost, and resources. Read more about how we work with our customers to design and build universal test systems in our white paper.

Blog Comments