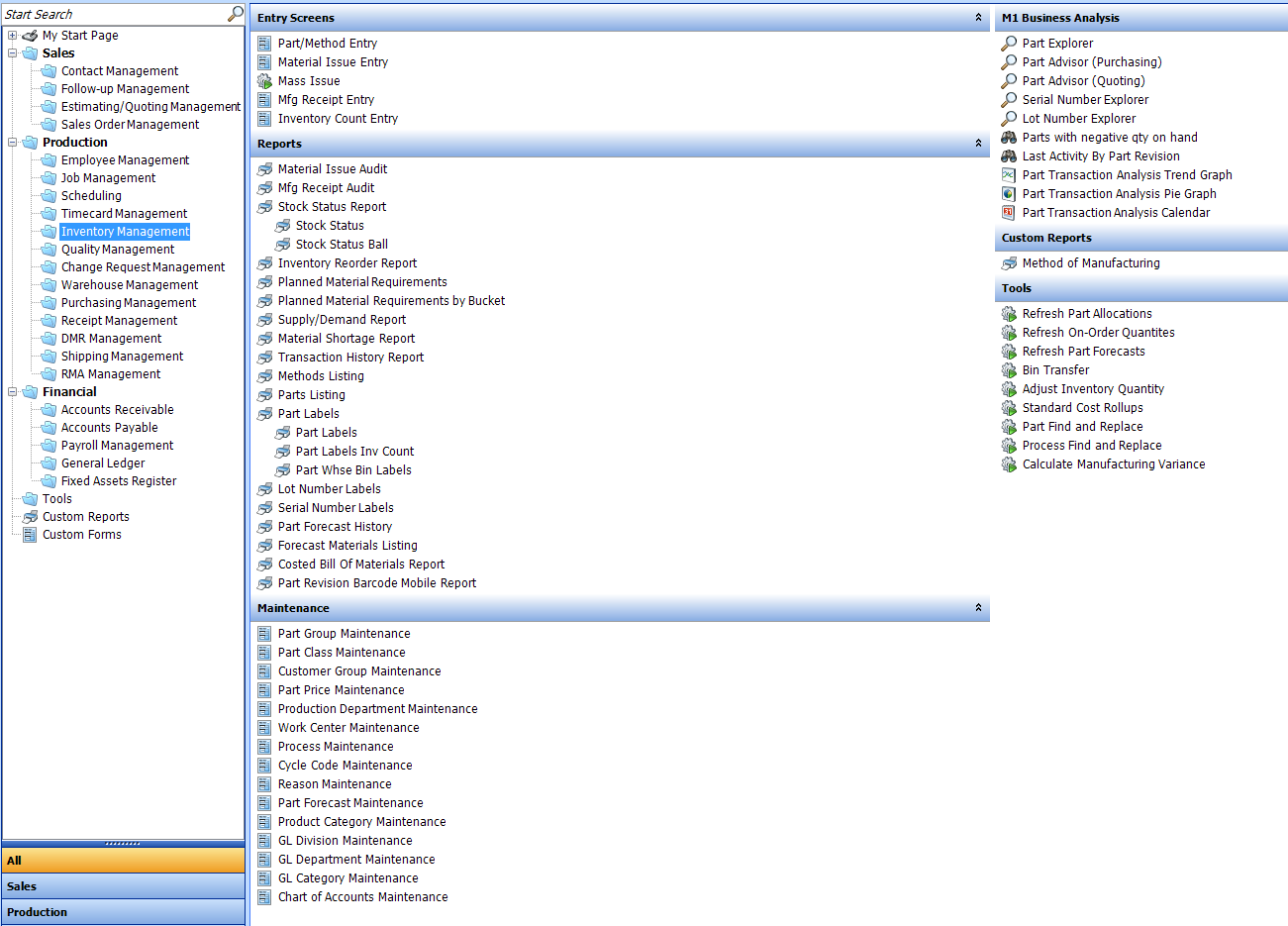

Choosing a turnkey build-to-print partner like Ball Systems can save you time and money by producing precise high-quality copies of your test system or product. We know a large part of this value comes from our ability to provide the customer with an accurate and up-to-date status throughout all stages of the build process. To accomplish this, Ball Systems leverages all of the resources available in our ERP system.

By using the latest ERP software, Ball Systems project engineers are able to provide you with added value from the purchasing phase all the way through and even after the order has shipped. Just a few of the ways we do this are:

Ball Systems can manufacture a wide range of products. Often these test systems can consist of hundreds of individual pieces. When purchasing parts, each piece is bought specifically for your order. This allows us to track every material down to the individual screw, resistor, or cable. By doing this we can quickly provide you with a picture of where the materials for your order are. This allows Ball Systems to easily answer questions like an expedite request or how a back-ordered part may impact delivery. This provides our customers with peace of mind knowing they will be informed.

Upon receipt of each piece at the Ball Systems facility, job materials are tagged with a custom label generated by our ERP software. This allows our technicians to quickly identify each piece when starting a build. As a result, we are able to spend less time organizing parts and more time assembling your order. This is especially true on large systems that may have several similar, but slightly different parts (for example different relays from the same series).

Not all design documents that our customers provide for orders are perfect. This may be because it is a first-time build or because the part has not been built for some time and components are now obsolete. No matter the reason, this isn’t a problem for us. At any point during or at the completion of the job, the Ball Systems project engineers can access the ERP system to provide an updated bill of materials (BOM) that can be used to modify the design documents - this way you don’t have to worry about missing any changes.

Even in cases that don’t directly require an update to the design documents, there are often lessons learned that we can apply to future orders. This might be part specific like what tooling is needed to install. Or at a higher level - like what build order the assembly needs to be performed. In either case, we can note these things in our ERP software. These notes can be programmed to show up were only relevant. For our customers, the more we build similar products, not only are we able to provide higher quality but also able to build them faster and thus lower our costs to you.

Learn how our bespoke build-to-print solutions can be a fit for your next project.

Blog Comments