Product development cycles are moving faster than ever, particularly in industries like aerospace, defense, automotive, medical devices, and consumer appliances. As system complexity increases, engineering teams rely on a rigorous testing framework to validate performance, reduce risk, and accelerate time‑to‑market.

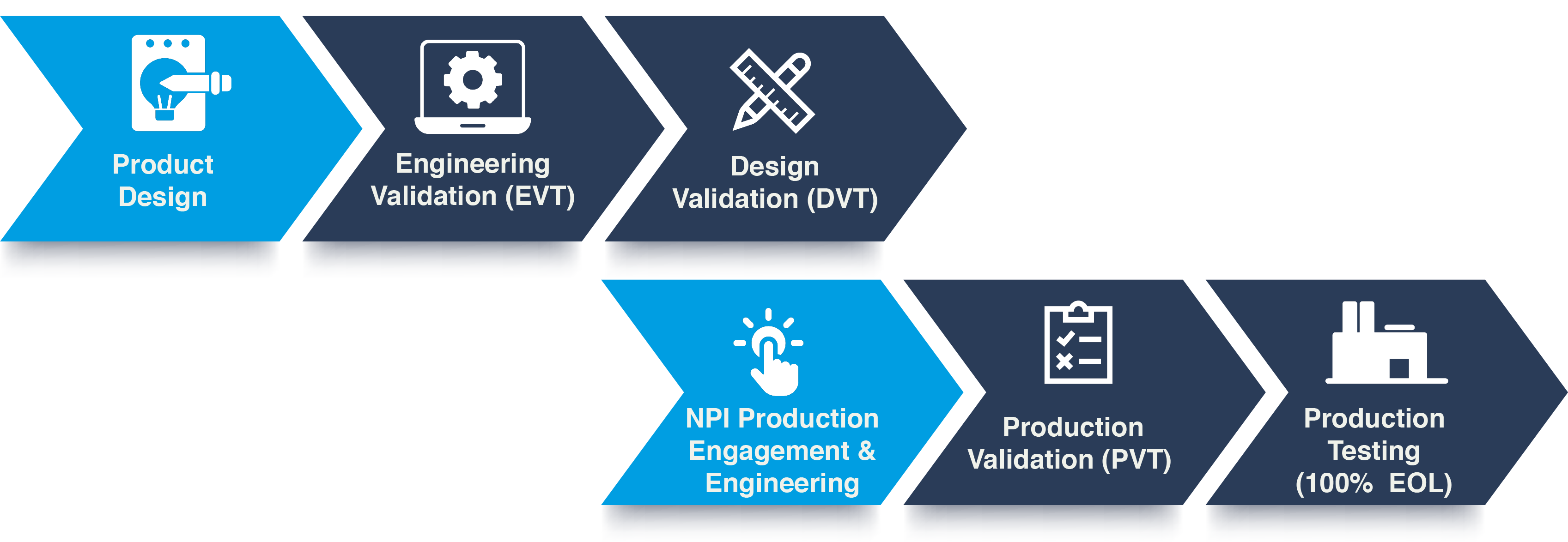

Below is a comprehensive look at the three core testing phases: Engineering Validation Testing (EVT), Design Validation Testing (DVT), and Production Validation Testing (PVT).

Navy Blue = Functional areas where testing is developed and utilized

The testing needs of each are highly differentiated as a result.

Simply put, does the design work? EVT validates that the early prototype meets engineering intent. Modern EVT relies on rapid prototyping, early firmware bring‑up, interface testing, environmental screening, and digital twin modeling. It identifies early risks before moving into costly tooling.

Does it meet specifications and compliance requirements? DVT confirms the design satisfies performance, durability, and regulatory needs. Testing now includes HALT/HASS, EMI/EMC pre‑compliance, integration tests, reliability studies, and automated test system workflows.

Can we build it repeatedly and reliably? PVT evaluates manufacturing readiness. Pilot production, SPC, tooling verification, end‑of‑line automation, and MES‑linked traceability ensure repeatable quality and yield.

Because of these three separate and distinct phases, test departments typically only focus on their share only, ignoring or being oblivious to the other sections who might be tackling similar problems on the same project.

These organizational silos cause lost long-term savings and company-wide efficiency issues.

Download our white paper, Leveraging Common Test Platforms Across The Product Lifecycle, to learn how to use common test platforms to optimize testing strategies across multiple departments:

Blog Comments