When planning out projects with our customers in the quoting process, we walk through a variety of considerations to determine find the best fit for their unique needs. But rather than require one or the other, we often find the best approach for a project is to design a hybrid solution that ensures our clients receive the best results at the lowest possible cost.

That’s the first question your test integration provider should be asking you. If you’re evaluating a test partner, you want to find a group that will start by assessing your specific project and develop a system that meets its unique requirements. You don’t want to feel trapped by a partner that wants to squeeze your project into a pre-determined system. They will be unlikely to meet your needs.

Off-the-shelf equipment or a commercial-off-the-shelf solutions (COTS) is often effective, less expensive and more reliable than a custom solution. At Ball Systems, we select parts that we have used time and time again, so we know what to expect from its performance. We’ve worked out the bugs for these parts and know the technology is reliable. Beyond reliability and quality, using standard components whenever it's most effective in a unique design also reduces engineering time – which saves you money and decreases your risk and lead time. You don’t want to wait around for engineers to reinvent the wheel just so you can get your project moving.

But we also want to add the customization required to design the best possible project. I’ve never been a fan of a simple platform that is unable to bend to a customer’s need. Avoid hiring a provider that attempts to shoehorn you into a standard system. Some may only be able to leverage what they’ve already done and overlook what you really need. At Ball Systems, we can supplement standard subsystems and COTS components with customization in our design work. By having fundamental building blocks in place, we can be cost-effective and expand the system to suit your specific needs.

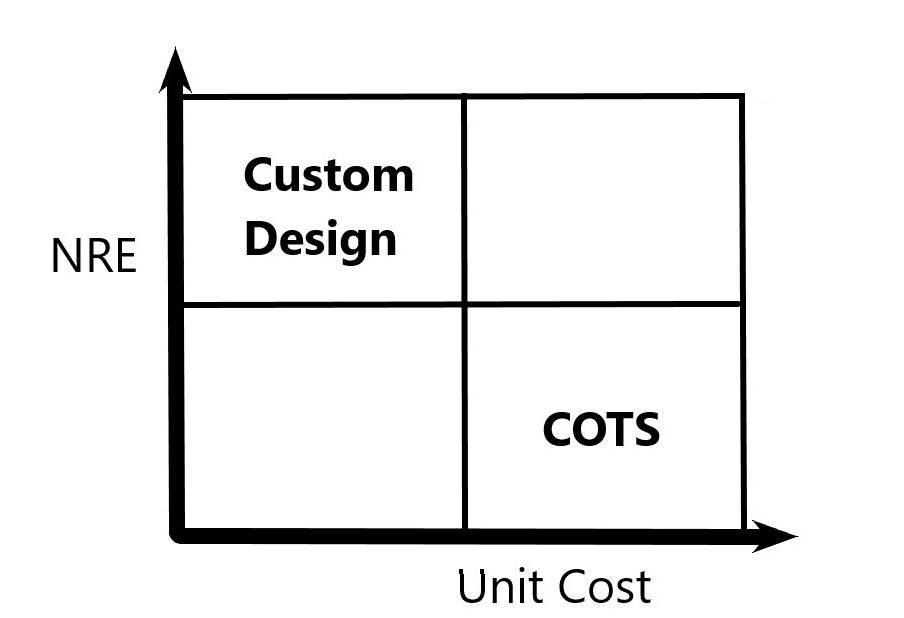

As I’ve written before, it’s ideal to find the solution that includes both the most cost competitive product available and the right fit for performance. When evaluating your budget and project scope, it’s also important to run a cost analysis based on the number of units this project will require and how that will ultimately impact the company’s bottom line. You may have a budget that’s more COTS-friendly now but the argument for investing in a higher non-recurring engineering (NRE) solution that will lower your unit cost will make a lot of sense if it saves you a big sum in the long-run.

So ask your test solutions provider: What is the projected NRE for a custom design? What does a COTS solution cost?

We’ve worked through this equation with customers countless times before. With one project, we had a client that planned to move their manufacturing lines outside the country but had an old hodgepodge system that they didn’t document well and wasn’t going to be easy to move. They needed a universal test solution. We were able to leverage standard subsystems and COTS components to provide them a reliable solution that was easiest to maintain. However, they also needed special functionality and required a custom interfacing solution.

It would’ve been easy for this group to hire a provider with a one-solution-fits-all system that may have been capable to complete most of the necessary requirements. But over time, they wouldn’t have had the unique functions available they needed, and the amount of money and time wasted working around that problem would have slowly piled up.

They would’ve conformed to whatever their provider could solve instead of being delivered a solution best fit for the project.

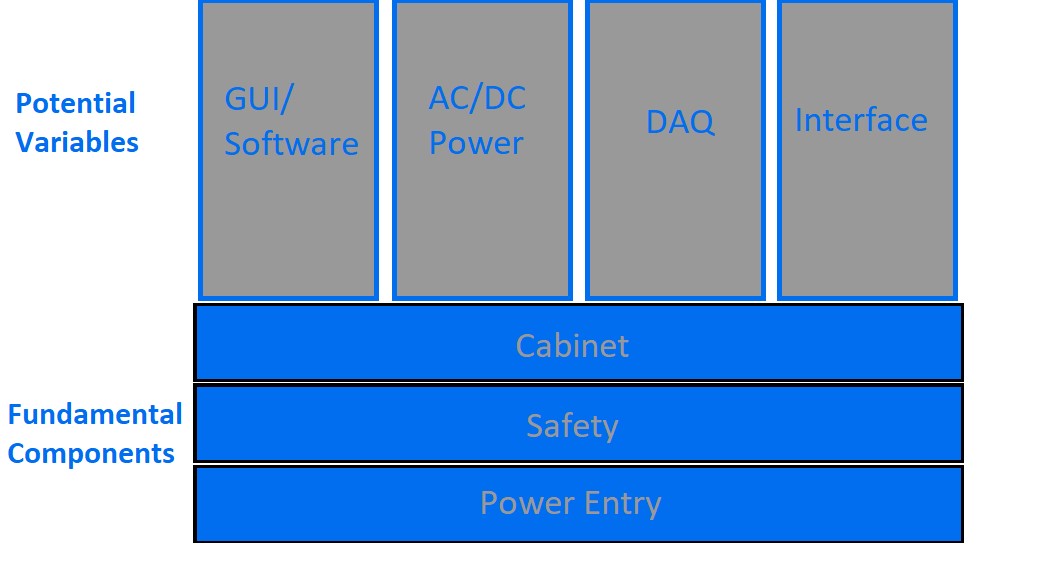

Here is an example of a process we would go through with a customer to develop the right electronics test solution. First, we assess and evaluate their needs and find fundamental components we often reuse – especially with power entry, cabinets and safety features.

Then, we’d look at potential variables in a system that might require a higher NRE, custom design. This may include software considerations, interfacing needs, DAQ, AC/DC power and more.

If your provider isn’t going through a similar process, they may charge you unnecessary NRE, attempt to provide an insufficient system or a deliver a solution that does everything you need but also includes so much more than necessary and you will overpay for it. Flexibility is important. Anything less reminds me of that Henry Ford quote about finding the right color for a customer’s new Model T: “Any customer can have a car painted any color that he wants so long as it is black.”

Hiring a company that has also handled a high-volume of design projects can make a big difference. Instead of paying for their learning curve, when you work with a test solutions provider that’s worked through similar problems to yours, they’ll move faster and you’ll save money. They’ve gone through the process before and know how to ask the right questions to get the best answers. You won’t buy unnecessary parts or end up with an insufficient solution.

Blog Comments